The story started with grinding

As a professional of cutting and grinding, we keep on trying on a daily basis!!

We excel at cutting and grinding processing for various non-ferrous metals including stainless steel (SUS), aluminum, titanium, and Inconel. While working on challenging processing, such as microfabrication and difficult-to-cut processing, we prototype and assemble metallic, plastic and resin products, and promptly deliver these products from a single unit to a large quantity. We offer products and services to our clients in a wide variety of industries, including processing of automotive parts, precision machine parts, and parts for special machines such as for liquid crystal film, food, and medical devices.

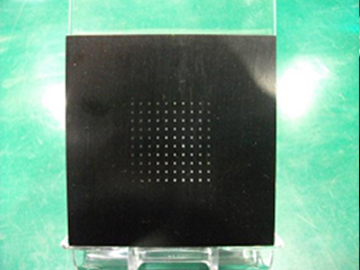

Our unique pinhole microfabrication and deep hole processing

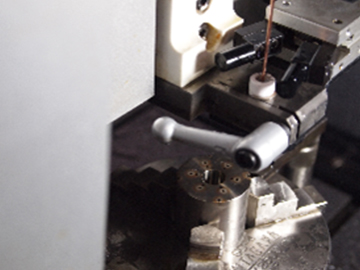

Introducing the pinhole electrical discharge machine enables us to process a hole of φ 0.25mm.

We had exceled at microfabrication even before we introduced this machine, while a hole of φ 1mm or smaller was very difficult to process on a stable basis. But the introduction of this processor solved this problem and broadened processing ranges.

Count on us with processing of pinholes and deep holes.

Lathes and milling machines

Lathing and milling serve as the basic processing technology. We train all the employees to the extent that they can operate lathes and milling machines at a professional level.

Obinata Seimitsu Kogyo’s quality underlies this basic processing technology.

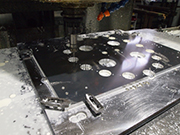

Machining

We possess 7 machining centers, including the one that can process works up to 1600mm.

Since these machines are used for precision processing, we conduct secure maintenance work so as to enhance our product quality.

Wire cutting and other processing

In addition to machine processing, we have wire cutters.

In order to respond to a request of producing irregular products, we establish a unique network with good-standing factories according to the following six categories: lathing, milling and machining, grinding and polishing, laser welding, hardening, and surface finishing. We are always ready to respond to your requests regarding precision cutting and grinding, as well as other processing.